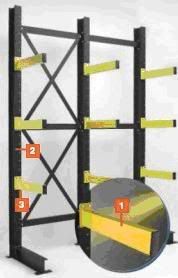

Cantilever Racking Systems

Cantilever Racking Systems are designed for the safe and efficient storage of longer or bulkier products. It maximises storage space with easy accessibility and excellent product presentation. Cantilever Racking is an adaptable and flexible system that allows for safe, convenient storage for a variety of products. It has no front columns to interfere with the placement or retrieval of loads.

Functions of Cantilever Racking Systems

- Safe and neat storage of long products

- Maximises usage of floor space

- Each rack designed and manufactured to suit individual requirements

- Robust design to cope with arduous environments

- Ideal for plywood & timber, building materials, pipe & tubing, sheet steel, goods, extrusions

Features & Specifications of Cantilever Racking Systems

- Arms positively secured in position using two high tensile, zinc plated bolts

- Arms adjustable on a typical pitch of 150 mm, which can be varied if required

- All upright and base sections are manufactured from hot rolled universal beam sections

- Arms manufactured from universal beam or rectangular hollow sections

- The latest computer technology is used to achieve the most efficient design

- Minimum safety factor of 2.8 based on ultimate tensile strength

- Arm deflection limited to 1/150 of length

- Upright deflection limited to lesser of 1/120 of height or 50 mm

- Maximum allowable weld stress of 115 N/mm 2

A cantilever is a beam that is supported at one end and carries a load at the other end or along its length, having the other end suspended in the air. The beam forms a lever, which carries the load by being held in position by the mount, turning the loads into torque on the mount.

Cantilever construction allows for long structures without external bracing which comprises of:

1-Cantilevered beam

2-Supporting post

3-Location of torque

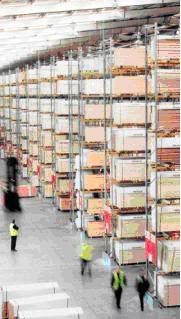

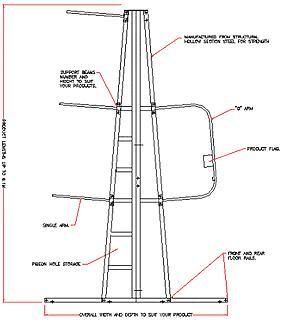

Vertical Racking System

Vertical racking is designed for vertical storage of tubing, pipe and other types of similar materials. It enables the organization of pipes, extrusions etc. in a systematic and readily accessible manner. Vertical racking utilises the minimum amount of space for storage of products.

Features & Specifications of Vertical Racking System

- Sturdy construction which supports the items

- Arms adjustable horizontally without use of tools

- Standard location depth 600 mm but any depth available

- Bay centres designed to suit space available

- Heights from 2 metres to 6 metres

- Single- or double-sided

- Floor retaining angle keeps stock safely in rack

Palletstor Racking System

The Palletstor racking system is the solution to all heavy-duty storage applications.It is one of the most widely used pallet racking systems available today which has evolved through in-depth knowledge of storage and handling techniques gained during many years experience in the industry.

Features & Specifications of Palletstor Racking System

Adjustable But Strong & Rigid

Beams can be removed and repositioned when changes in the use of the racking occur. Although Palletstor is adjustable, once the beams are slotted into position in the frame uprights, an inter-locking structure of great strength and rigidity is maintained. Each beam is supplied complete with a pair of steel Safety Locking Pins. When located they ensure the beam is correctly positioned and help prevent the beam being dislodged during use.

Palletstor racking beam with safety locking pin

Palletstor racking beam with safety locking pin

Safety locking pin

Safety locking pin

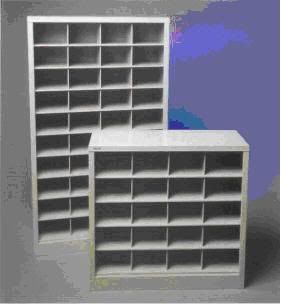

Pigeon-Hole Racking

Pigeon-Hole Racking is suitable for a wide range of products and applications. It allows easy identification and retrieval of materials and suitable for automobile parts, hardwareitems and for many other products.

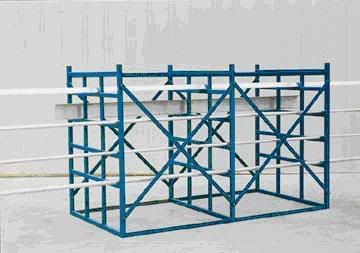

Heavy Duty Systems

It is also known as Pallets Racking system. This storage system is designed to take maximum load upto 2 tons per load.

Applications

This design is suitable for Raw-material and finished product storage for each & every industry.