(A) DYNAMIC SYSTEMS

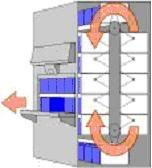

Effectively utilising floor and cubic space, dynamic push back racking is amongst the most space efficient pallet racking storage systems available. Push Back uses gravity fed telescoping carts to provide high density dynamic storage. Pallets are loaded in sequence onto wheeled carriers of differing heights and are pushed back along inclined steel guide channels to utilise the full depth of the pallet racking. Pallets can be stored upto four deep and when a load is retrieved the remaining pallets roll forward into position at the picking face.

Pallets retrieved on a ‘first-in, last-out' basis and with each product having a dedicated lane. Dynamic push back racking is particularly useful in marshaling areas, and for long term storage and handling.

Benefits:

- Exceptional space utilization

- Good aisle selectivity

- More picking faces/ fewer aisles

*Available in Roll Form or Structural Materials

Push back racking

A dynamic storage system where pallets are stored two, three or four deep. Pallets are placed onto the front position and subsequent pallets are then added by 'pushing back' the front pallet. Retrieval is the reverse of this procedure with pallets returning under gravity. This system can be accessed using most standard types of fork-truck.

Carton Flow Racking

Carton live storage or ‘flow racking' operates on the same principle as pallet live storage, but is used for stock which needs to be hand-loaded and picked. Live storage systems reduce order picking times and help minimise errors, as not only are items presented precisely at the picking face, but effective management of the throughput and stock levels of goods can also be easily maintained.

(B) MECHANISED SYSTEMS

Carousel systems are automated storage and retrieval systems (ASRS) which are made of shelves / bins and chains and are operated electrically to store and retrieve stocks to workers' locations as required (parts-to-picker).

Advantages of Carousel Systems:

- Minimise operator dependency & movement

- Improve inventory accessibility & security

- Improve order picking efficiency & productivity

- Time & cost savings

- Cubic utilisation

2 Types of Carousel Systems:

1) Vertical Carousel System

- Similar to High Bay but without loss of storage space

- Compact shelves geared to size & weight of articles stored

- Height Optimisation

- High flexibility

2) Horizontal Carousal System

- Series of storage bins suspended from a horizontal, continuous overhead chain

- Bins rotate in a closed-looped oval track

- Requested items routed to operator or picker

- E.g. Hospitals