A) LIVE STORAGE

Pallet Live Racking

Working on a ‘first-in, first-out' basis, dynamic live pallet racking provides extremely high levels of storage density in a given area. Pallets are loaded onto dedicated lanes of inclined gravity feed rollers which are set at a fixed gradient. When a load is taken from the picking face, the next pallet rolls into position, with replenishment stock loaded at the opposite (upper) end of the lane. Stock rotation is therefore automatic with the minimum of fork lift truck movements required to handle the flow of goods.

Fast Pallet Access

Pallet loads can be entered and removed from single dedicated lanes. Gravity tracks are set at a fixed gradient allowing pallet loads to roll from the input face by gravity to the output face, eliminating fork lift truck movement.

System Flexibility

The dynamics can be specified to suit a wide load range. Speed controllers provide regulated movement of pallet loads to the pick face. Rollers, uprights and beams can be made to any length to suit the pallet/product size. The fitting of a pallet separator at the output position of each lane will allow zero line pressure.

‘First in'-‘First out'

Speed of throughput combined with automatic stock rotation is the major advantage of this system.

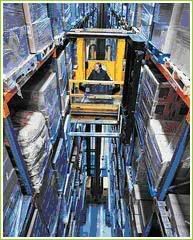

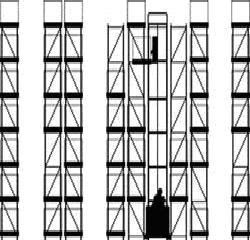

B) HIGH RACK NARROW AISLE RACKING

- Narrow Aisle Rack is a high density type of Carton Storage System that offers immediate access to every carton stored in very narrow aisles.

- Narrow aisle racking is served by specially designed trucks or stacker cranes.

- Narrow aisle free path stackers are equipped with rotating or sliding pallet handling mechanism on the mast, which do not have to turn through 90 degrees in the aisle to pick up or set down a pallet load.

- The gangways are only marginally wider than handling equipments.

- If trucks are used, the guide rails or electrical wire guidance will be used to constrain and guide the trucks along the gangways and not to turn to retrieve or deposit a pallet. The mask or fork head rotates to left or right as required.

- Narrow aisle truck can operate to greater heights than conventional trucks - up to 14 m.

- Specialised forklifts called Turret (turret trucks are expensive) or SwingReach trucks and Automatic Stacker Cranes (AS/RS) that operate in aisles not much wider than the load itself, can increase the use of available space. Head space too is effectively used in high-rise narrow aisle applications. Although capital cost typically increases, there are usually savings in land and building costs.

- Narrow aisle racking consists of the same basic components as conventional racking but with runs placed closer together eliminating the wasted space of a wide aisle. The pallets can be stored to a greater height to maximise all available cubic space. The pallets are accessed via specialist trucks, which are guided in the very narrow aisles by either low or high profile floor mounted rails or electronic wire guidance in the floor.

- The principal advantages of narrow aisle racking includes:

- The combination of relatively high density with 100% individual selectivity

- Throughput speed can be more rapid than with conventional trucks and layouts

- 100% accessibility to individual pallets

- Configuration for maximum storage, density and efficiency

- Specialist narrow aisle fork-lift trucks are required to work in the reduced aisle

- Better space utilisation

- Good occupancy rates

3-D Diagram

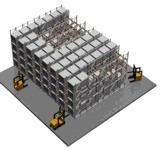

C) HIGH BAY

- The automatic storage of pallets in high bays is an efficient way of storing a large number of different articles. All in and outfeed via stacker cranes and conveying systems in front of the high bay are carried out automatically.

- Controlled by Windows-based software.

- High bay pallet racking can reach up to a height of 30M to 35M.

- Racking for fully automatic installations.

- High-bay solutions reduce the cost of space needed for storage while offering all of the benefits of automation. Working either with pallet or other unit loads or mini-loads, including cases and totes.

- High-bay storage solution enables higher throughputs and space utilization, as well as increased order accuracy and inventory control.

- Fully automated high-bay AS/RS solutions allow 24/7/365 operation that provides labor savings, improved productivity and substantially reduced downtime.